Powerful roundness measurement system for production workshop, specially designed for high-throughput production environments that require high-speed and accurate measurement. This system uses an air bearing spindle with manual centering and leveling functions.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

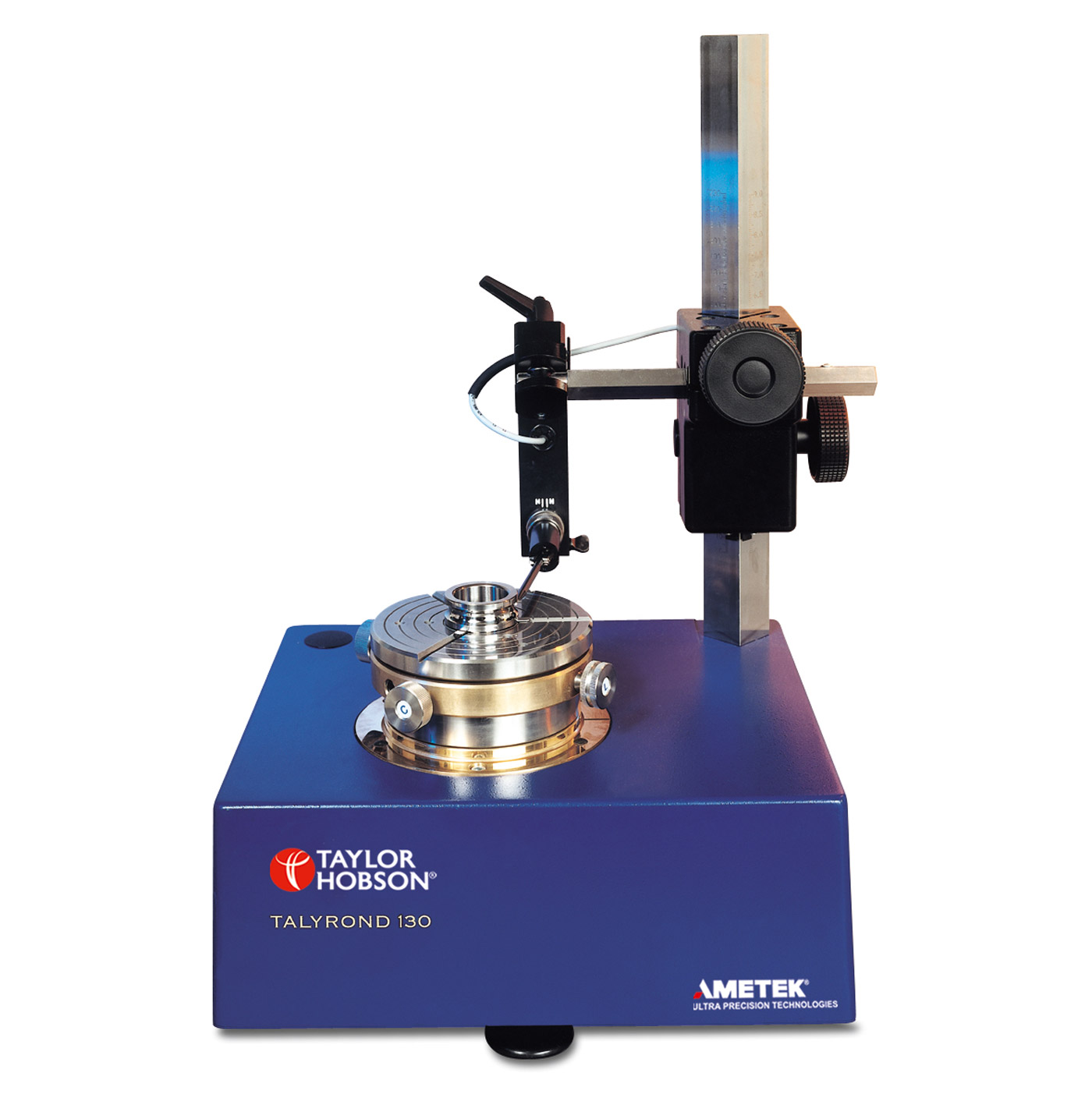

Talyrond 130 Economical high precision roundness measuring instrument

|

The Talyrond 130 is equipped with positive friction positioning controls on both the column and the cross arm. The secondary direct drive can respond to REEDIT's large distance movement and make the operation of the moving hand wheel more compact. Greatly reduced drift, backlash (tilt) without the need for heavy, inefficient fixtures. ● The program can carry on man-machine conversation ● Rugged, compact structure that fits anywhere in the factory ● Marking for precise positioning ● Independent electronic interface module Length = 250mm (10 inches) Width = 160mm (6.3 inches) Height = 80mm (3.2 inches). |

|

|

Measurement superiority: |

|

The superiority of any metering device depends on its resolution range. Taylor Hobson's sensor head has a large measurement range and selectable resolution, which greatly improves measurement accuracy during manufacturing |

|

Powered by Ultra Roundness Software |

|

This software provides comprehensive analysis and programming measurement capabilities for Talyrond 131C and 130, making it as the ideal software for performing fast part measurements in any environment. |

|

Mechanical superiority during measurement |

|

1) Air bearing spindle for diamond turning Spindle accuracy is critical to the performance of any roundness meter. Radial error refers to a constant value measured at the top of the table; conical error is the degree of rotation of the main axis along its axis, which can increase with the distance from the top of the table. The radial error can be improved through software correction, but the cone error can only be reduced to a very low level through careful construction of the main shaft structure. Taylor Hobson's high-precision spindle is a combination of world-class precision and "rigidity." 2) Multi-purpose sensor The measuring sensor is installed as a "wrist" component to quickly switch between vertical and horizontal orientations, while keeping the stylus contact ball center point in contact with the workpiece. Internal and external surfaces can be measured vertically; surfaces above or below, external, angled or tapered can be measured horizontally. 3) High-density zinc alloy base The compact design is very important for workshops with limited bench space. Taylor Hobson uses special zinc alloy castings to ensure that smaller bench sizes do not degrade instrument performance. Instruments made from materials of this density remain extremely stable even under the harsh conditions of the production hall. 4) Integrated vibration isolation device In order to obtain laboratory-level measurement accuracy in the workshop, Talyrond vibration isolation pads are built into both 130 and 131C instruments. Unless it is a very harsh environment, in all other environments, there is no need to add additional anti-vibration materials. 5) Assisted leveling The centering and leveling knobs have different appearances and touches, which is convenient for the operator to adjust the workpiece to the instrument spindle while watching the screen. In addition, the design facilitates the leveling of short and long parts |

Talyrond 130 Economical High Precision Roundness Measuring Instrument

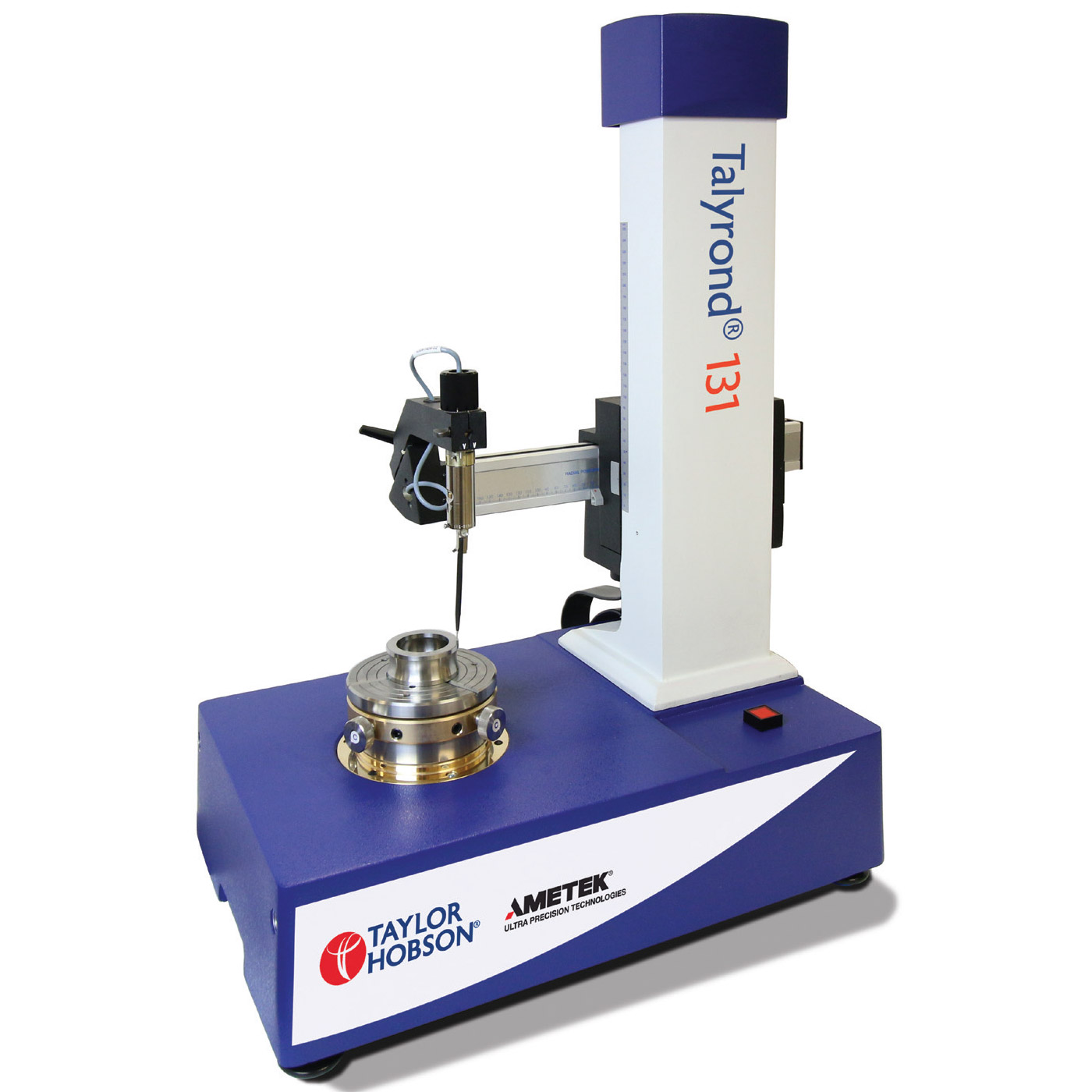

Talyrond 130 Economical High Precision Roundness Measuring Instrument Talyrond 131C Efficient Cylindricity Measuring Instrument

Talyrond 131C Efficient Cylindricity Measuring Instrument Talyrond 565 Roundness Measuring Instrument

Talyrond 565 Roundness Measuring Instrument Talyrond 585H series high precision roundness measuring instrument

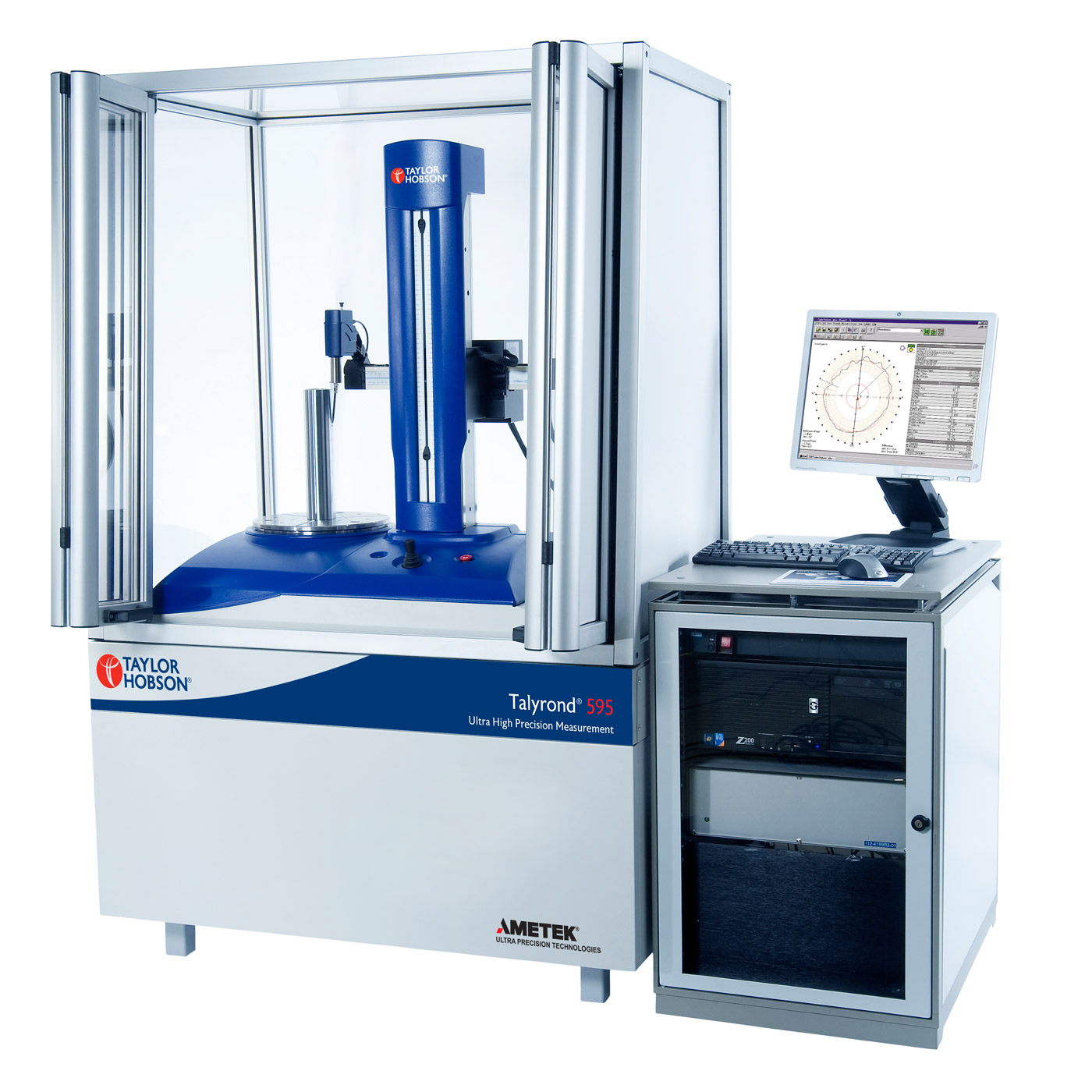

Talyrond 585H series high precision roundness measuring instrument Talyrond 595 High Precision Roundness Measuring Instrument

Talyrond 595 High Precision Roundness Measuring Instrument Talyrond 400H Series Cylindrometer

Talyrond 400H Series Cylindrometer TalyMaster Multi-Part High Precision Roundness Tester

TalyMaster Multi-Part High Precision Roundness Tester Talyrond 450 Large Roundness Measuring Instrument

Talyrond 450 Large Roundness Measuring Instrument Talyrond 565-585XL large roundness measuring instrument

Talyrond 565-585XL large roundness measuring instrument Surtronic R100 Series

Surtronic R100 Series

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號(hào)

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES