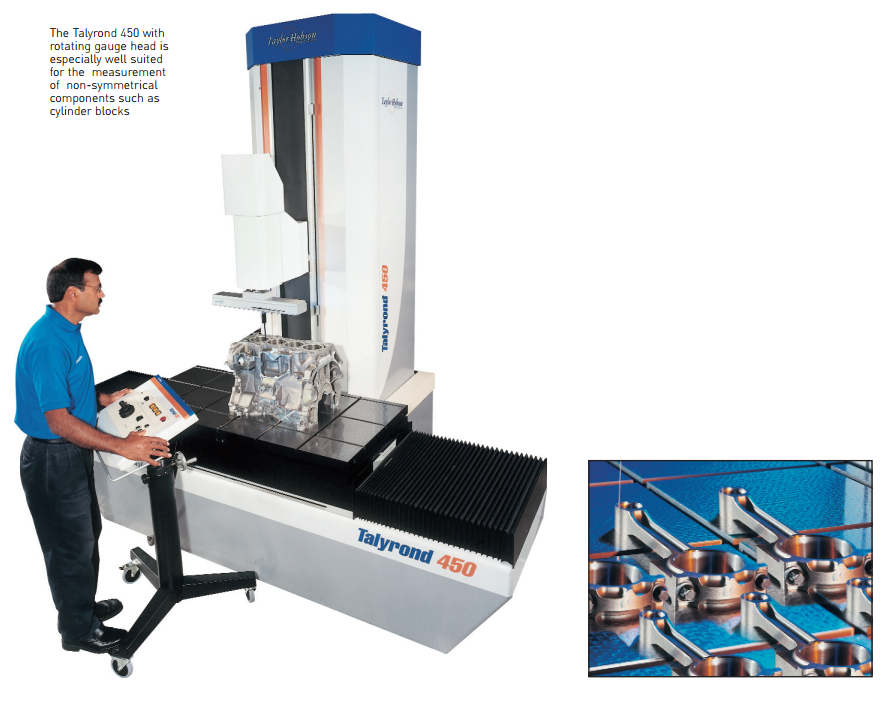

This series of instruments is designed for the power transmission industry and the machine tool industry. The instrument includes a rotating measuring head that can be moved up and down on the column. The use of a rotating measuring head allows the manufacturer to measure the roundness of prismatic or non-rotationally symmetrical parts such as cylinder blocks, crankshafts and cylinder heads.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

Talyrond 450

High-precision inspection of roundness and cylindrical geometry for large, heavy or complex parts

|

? Fully automatic centering and leveling ? Large X, Y table with high-precision position control with 1000 kg load capacity ? High load capacity, high precision spindle and dedicated deep hole measuring arm |

? Straightness, parallelism and cylindricity are measured up to 1.5m ? Optional column up to 2 meters ? Supported Ultra software for traceability to comprehensive measurements of national and international standards |

|

RONt |

Roundness |

CYLc |

Cylindricity |

|

STRt |

Vertical straightness |

Bounce (radial and axial) |

|

|

FLTt |

Flatness |

Full bounce (radial and axial) |

|

|

ECC |

Eccentric |

Harmonic analysis |

|

|

SQR |

Horizontal straightness, parallelism |

Partial arc |

|

|

CONC |

Concentricity |

Interrupted surface |

|

|

COAX |

Concentricity(ISO/DIN) |

Slope analysis |

Industry-leading mechanical performance provides accuracy and stability

|

● Stable structure The base and post of the TR450 are made of a stress-relieving alloy that has no other material to provide the same high stability and rigidity when measuring and moving loads. Therefore, the TR450's cylindricity accuracy is the highest in its class. |

● Powerful Ultra Roundness Measurement Software Ultra software provides powerful analysis and automatic measurement capabilities for the TR450. Ultra is an ideal tool when it comes to measuring workpieces quickly. |

|

|

● Stress relief Taylor Hobson uses two methods of stress relief, one after casting and the other before finishing. This ensures that the cast iron elements are incorporated into the upper structure of the instrument, maintaining a stable size and geometry. |

|

|

|

● Three-point kinematics leveling structure In the manufacturing industry, a surface is usually supported by three points. Taylor Hobson uses a fixed point and two other movable methods to level the workpiece. The TR450 uses this leveling method. |

||

|

● Precise position control We can program to control or correct the axial movement so that the operator can avoid errors. Precision linear sensors ensure accurate positioning. |

|

|

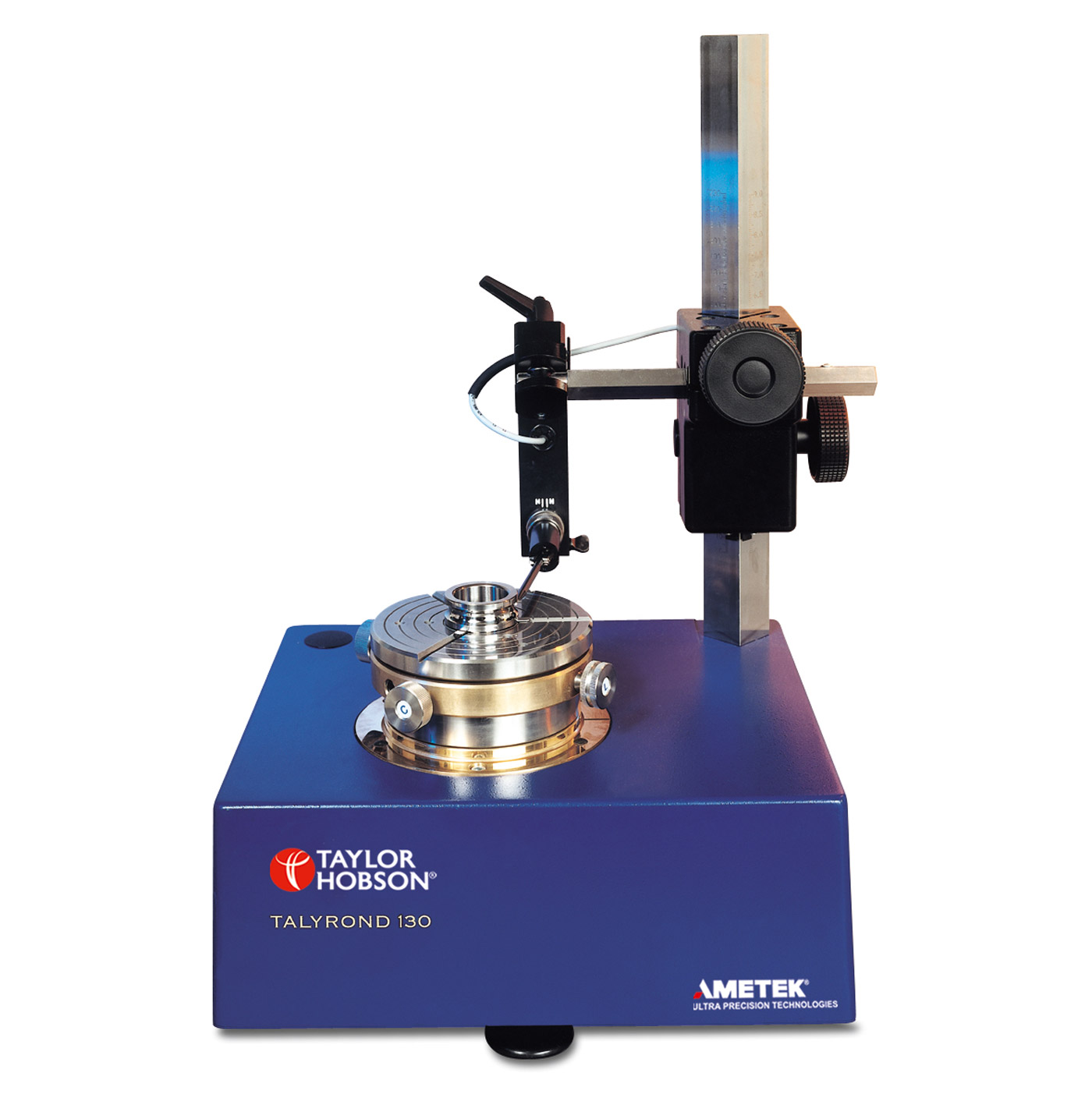

Talyrond 130 Economical High Precision Roundness Measuring Instrument

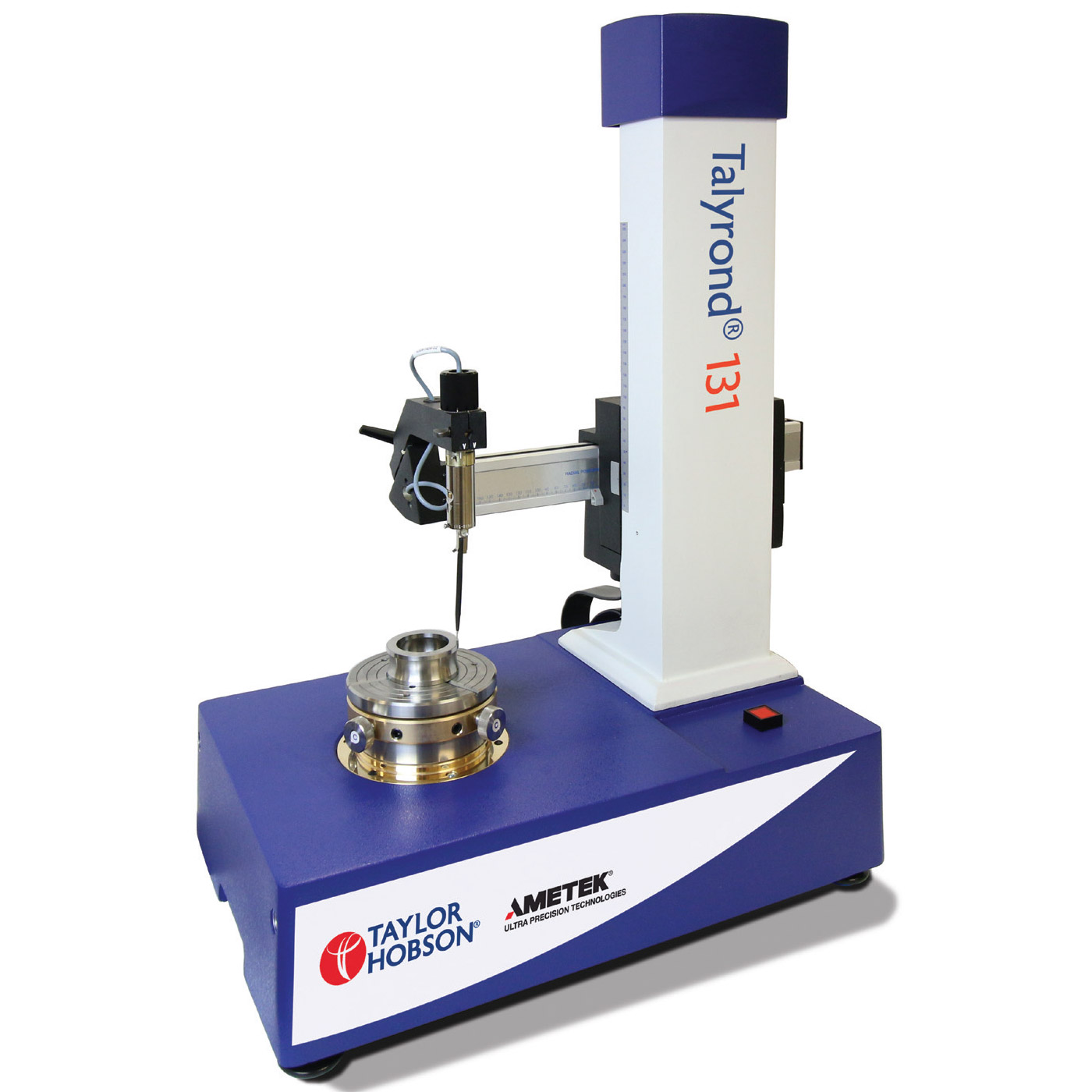

Talyrond 130 Economical High Precision Roundness Measuring Instrument Talyrond 131C Efficient Cylindricity Measuring Instrument

Talyrond 131C Efficient Cylindricity Measuring Instrument Talyrond 565 Roundness Measuring Instrument

Talyrond 565 Roundness Measuring Instrument Talyrond 585H series high precision roundness measuring instrument

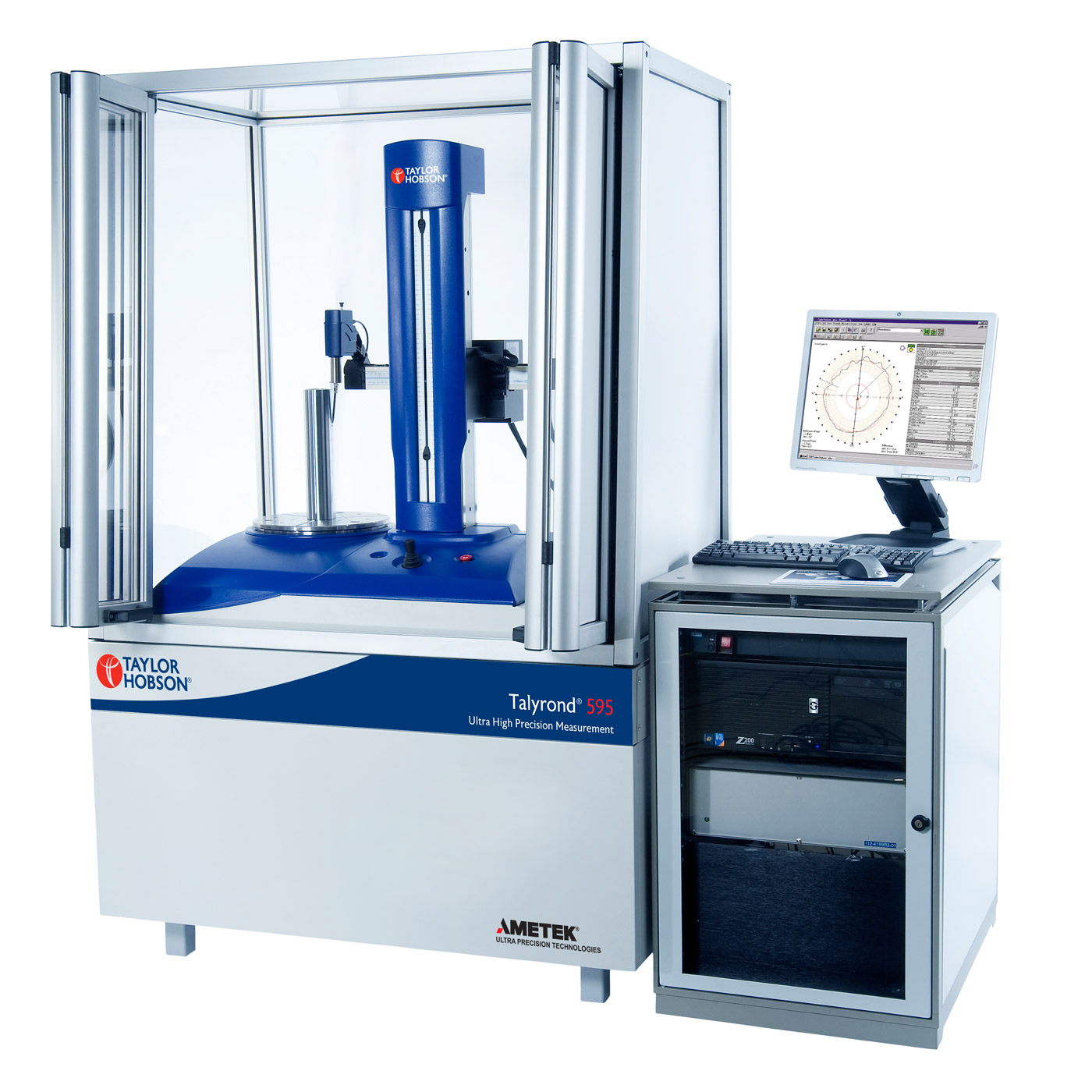

Talyrond 585H series high precision roundness measuring instrument Talyrond 595 High Precision Roundness Measuring Instrument

Talyrond 595 High Precision Roundness Measuring Instrument Talyrond 400H Series Cylindrometer

Talyrond 400H Series Cylindrometer TalyMaster Multi-Part High Precision Roundness Tester

TalyMaster Multi-Part High Precision Roundness Tester Talyrond 450 Large Roundness Measuring Instrument

Talyrond 450 Large Roundness Measuring Instrument Talyrond 565-585XL large roundness measuring instrument

Talyrond 565-585XL large roundness measuring instrument Surtronic R100 Series

Surtronic R100 Series

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號

滬ICP備12021537號-1

©2012-2024 LAB GAGES

滬ICP備12021537號-1

©2012-2024 LAB GAGES