This instrument was developed on the basis of Taylor's very popular Talyrond 565 series instruments. This series of instruments is particularly popular for the measurement of large-size bearings and asymmetrically rotating workpieces.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

Talyrond 565/585XL

High-precision equipment for measuring large-size components

The instrument automatically adjusts and leveles and automatically calibrates the sensor, thus increases measurement efficiency.

The system has two sets of devices for the user to select, fully automatic control of the measuring head rotation and manual control of the measuring head rotation. Both of these techniques measure workpieces with very complex shapes.

|

The Talyrond 500XL measures large components with a frictionless gas bearing spindle that adjusts the orientation of the workpiece and a high precision column. |

|

|

|

The measured part can be up to 1 meter in diameter This series of instruments is particularly popular for the measurement of large-size bearings and asymmetrically rotating workpieces. This instrument was developed on the basis of Taylor's popular Talyrond 565 series instruments. The system uses a frictionless gas bearing spindle that adjusts the orientation of the workpiece and a high-precision column to measure bearing diameters up to 1 m. |

Renewable measurement results Through decades of experience, the combination of precision machining expertise and FEA optimization design provides low noise and near-perfect mechanical measuring shaft operation. From the measurement results, the use of traceable standards and algorithms can be further enhanced to effectively eliminate the influence factors on the measurement results. |

|

●Self-aligning and leveling with horizontal tracking ●Automatic calibration sensor ●Two technologies, such as automatic rotation of the measuring head and manual rotation of the measuring head |

●Vertical straightness measurement column up to 900mm ●Large diameter measurement, multi-size column and 300mm cross arm ●Ultra software traceable to comprehensive measurement of national and international standards |

|

|

|

|

Asymmetrical power component |

Large diameter and high precision bearing |

Small jet engine and turbine engine components |

|

Measured asymmetric power train components |

Measuring large diameter high precision bearings |

Measuring small jet engines and turbine components |

|

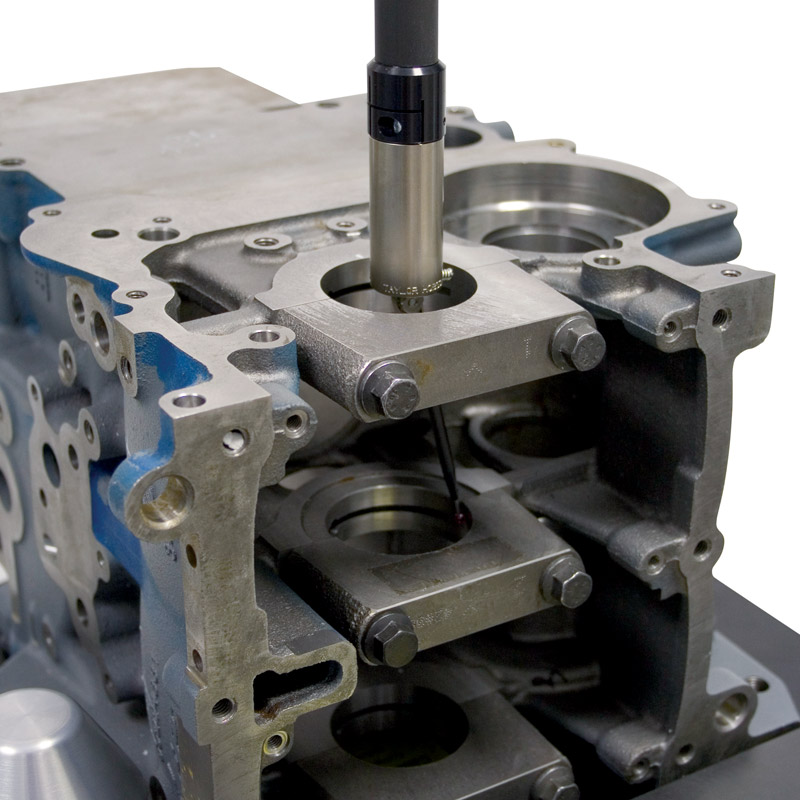

Most components are asymmetrical and can be difficult to measure with a conventional roundness meter. The test range of the XL series is designed to be relatively large and suitable for testing, such as connecting rods, engine blocks and cylinder heads. And the ability to measure asymmetric crankshafts, pistons, valves and cylinder liners makes it a very versatile roundness system on the market. |

The Talyrond 565/585XL is coming soon with a frictionless gas bearing spindle and high precision column for adjustable workpiece orientation. It can measure large diameter bearings, thanks to a high precision encoder with 72,000 data points resolution, high precision and high precision resolution. Coupled with the system's ability to measure roundness/flatness, each XL Series unit features harmonic and velocity analysis software, making it a powerful bearing surface analysis tool. |

Whether it's an engine component supplier or a manufacturer or repairer, the XL Series helps control engine efficiency and reduce engine build time through roundness, flatness and shape analysis. Parameters such as eccentricity and bounce can be added to their angular orientation to enable prediction and control imbalances, especially in the case of component stacking. Features such as harmonic analysis and velocity analysis can provide further predictions about information vibration and noise. |

|

Industry application |

|

|

|

●Automobile industry ●Aerospace ●Bearing |

●Hydraulic ●Optics ●Industrial plants |

|

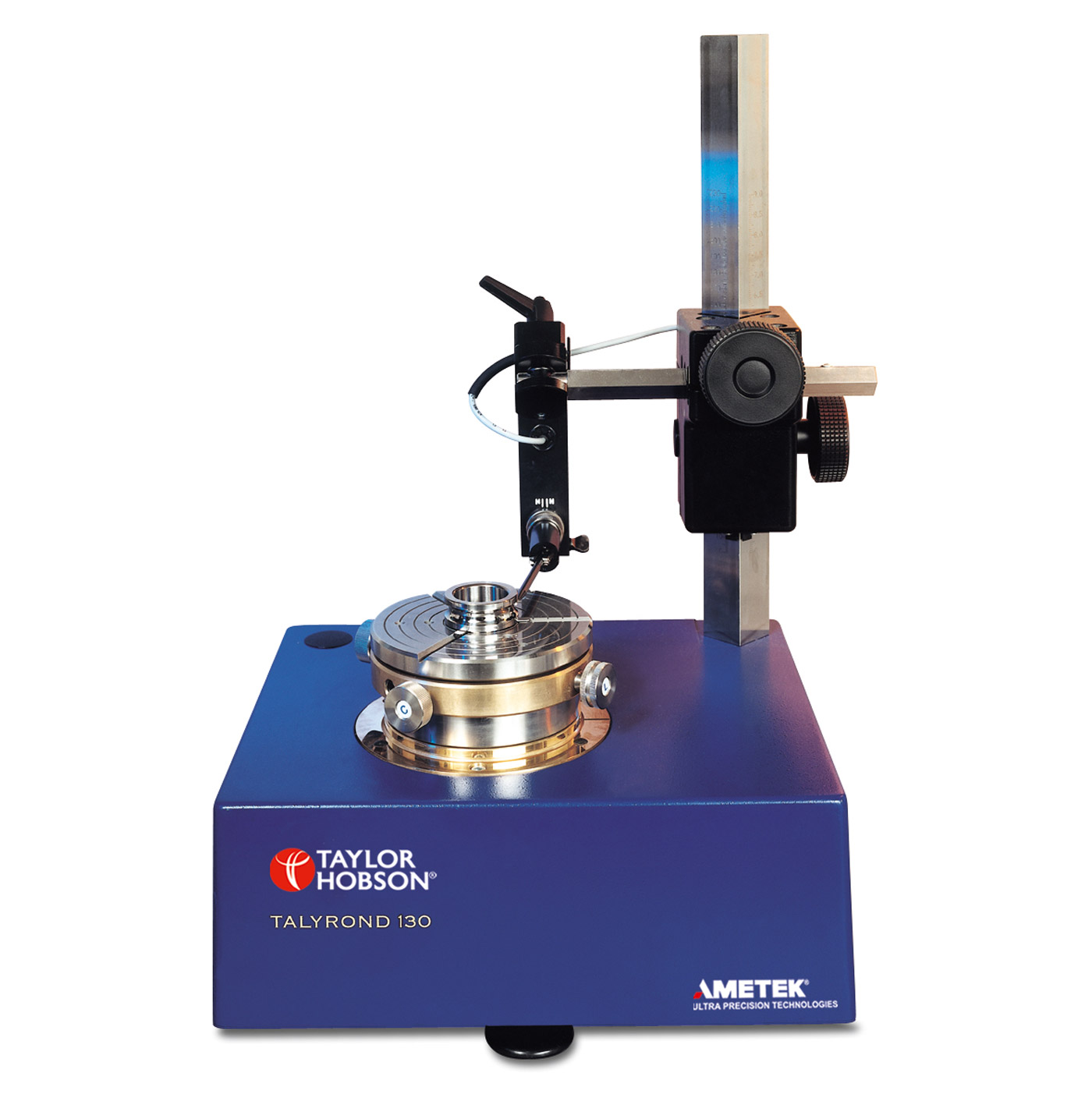

Talyrond 130 Economical High Precision Roundness Measuring Instrument

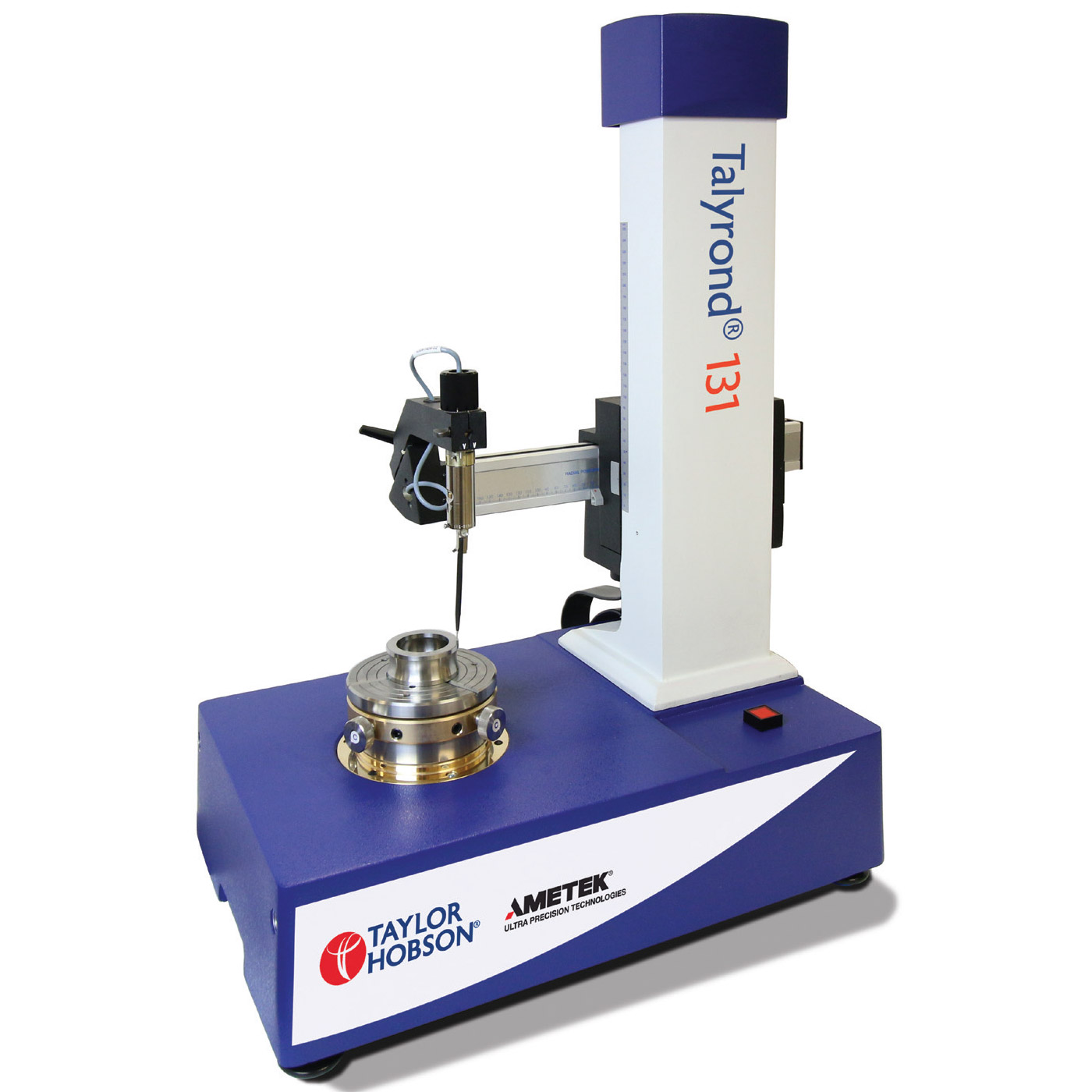

Talyrond 130 Economical High Precision Roundness Measuring Instrument Talyrond 131C Efficient Cylindricity Measuring Instrument

Talyrond 131C Efficient Cylindricity Measuring Instrument Talyrond 565 Roundness Measuring Instrument

Talyrond 565 Roundness Measuring Instrument Talyrond 585H series high precision roundness measuring instrument

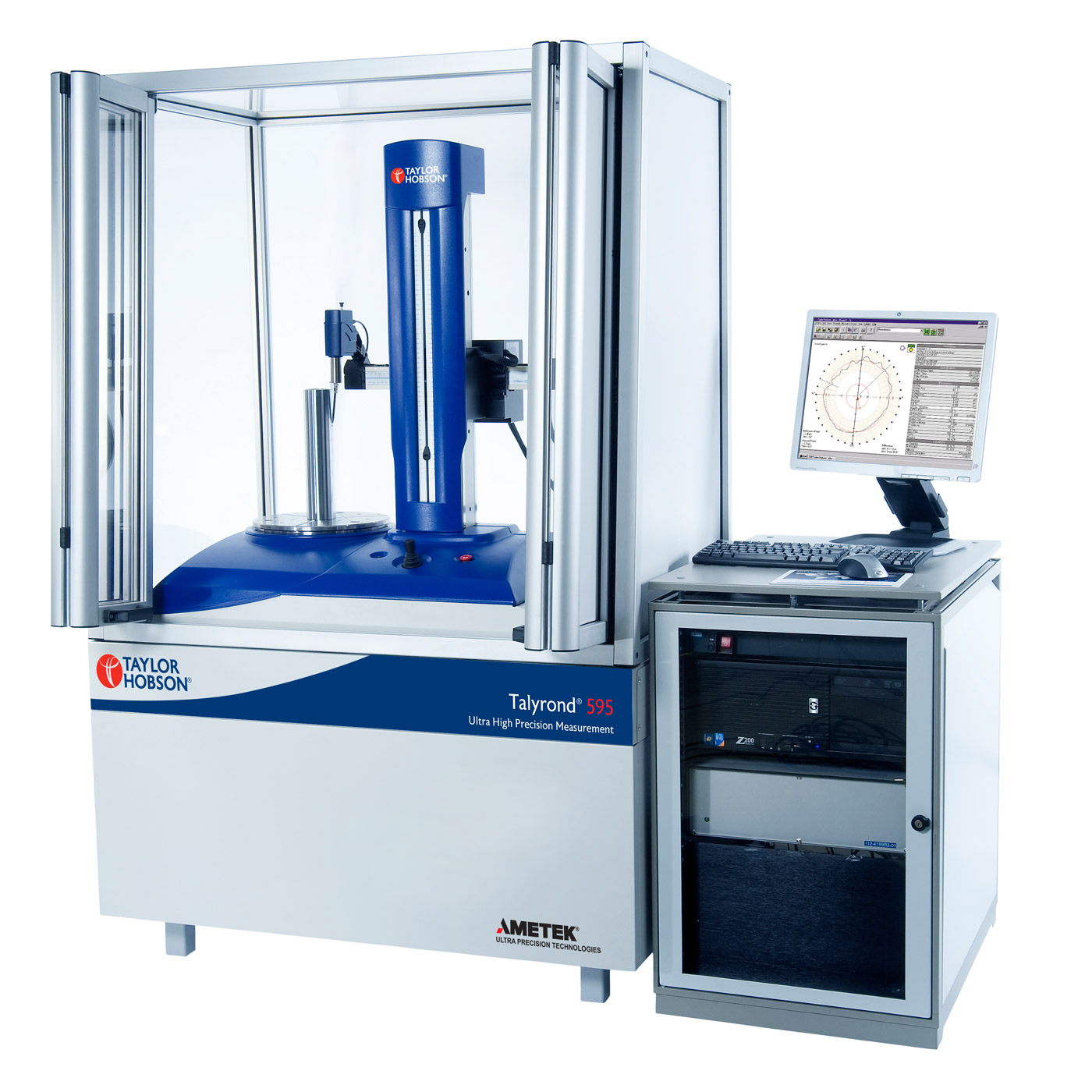

Talyrond 585H series high precision roundness measuring instrument Talyrond 595 High Precision Roundness Measuring Instrument

Talyrond 595 High Precision Roundness Measuring Instrument Talyrond 400H Series Cylindrometer

Talyrond 400H Series Cylindrometer TalyMaster Multi-Part High Precision Roundness Tester

TalyMaster Multi-Part High Precision Roundness Tester Talyrond 450 Large Roundness Measuring Instrument

Talyrond 450 Large Roundness Measuring Instrument Talyrond 565-585XL large roundness measuring instrument

Talyrond 565-585XL large roundness measuring instrument Surtronic R100 Series

Surtronic R100 Series

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號(hào)

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES