Smart combination of micromagnetic materials characterization and electromagnetic ultrasound transduction. Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel is demonstrator set up and testing in industrial-like environments.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

In order to enhance passenger safety and vehicle performance, reducing the weight of vehicles has become the top priority for the automotive industry today. Advanced High Strength Steel (AHSS) is the fastest growing material in today’s automotive industry and the key material when it comes to vehicle mass reduction.

Advanced high strength steels (AHSS) are used in the automotive industry for car body constructions in order to reduce vehicle weight (and therefore the CO2 equivalents) while maintaining or even improving safety and reliability of the construction. However, the beneficial properties of AHSS are much more sensitive to process variations than those of regular steel, raising the need for improved process monitoring and quality control. The same applies to other advanced steel qualities. So far, there is no comprehensive inline testing solution accounting for all parameters of interest. For example, mechnical properties, texture and grain size are still measured in the laboratory at randomly taken samples.

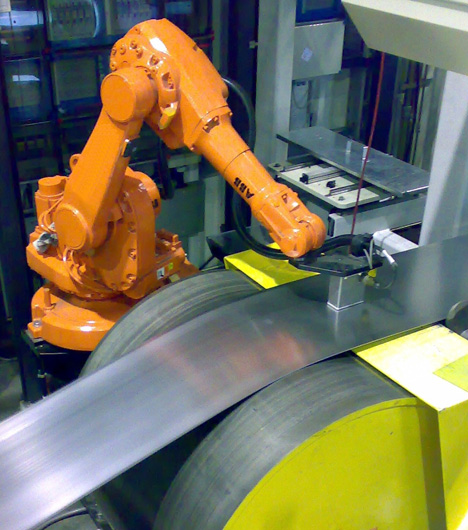

Rolled steel of advanced high strength steel

Rolled steel of advanced high strength steel

In the framework of MAGNUS, equipment will be developed which makes the combined methods available to a wide field of customers. The main application will be in strip steel industries, but the affordable multiple-probe support and high speed of the system to be developed will also serve other industrial branches such as heavy plate production and producers of components with recurring geometric features (camshafts, crankshafts, gears, bearings). MAGNUS zeroes in on:

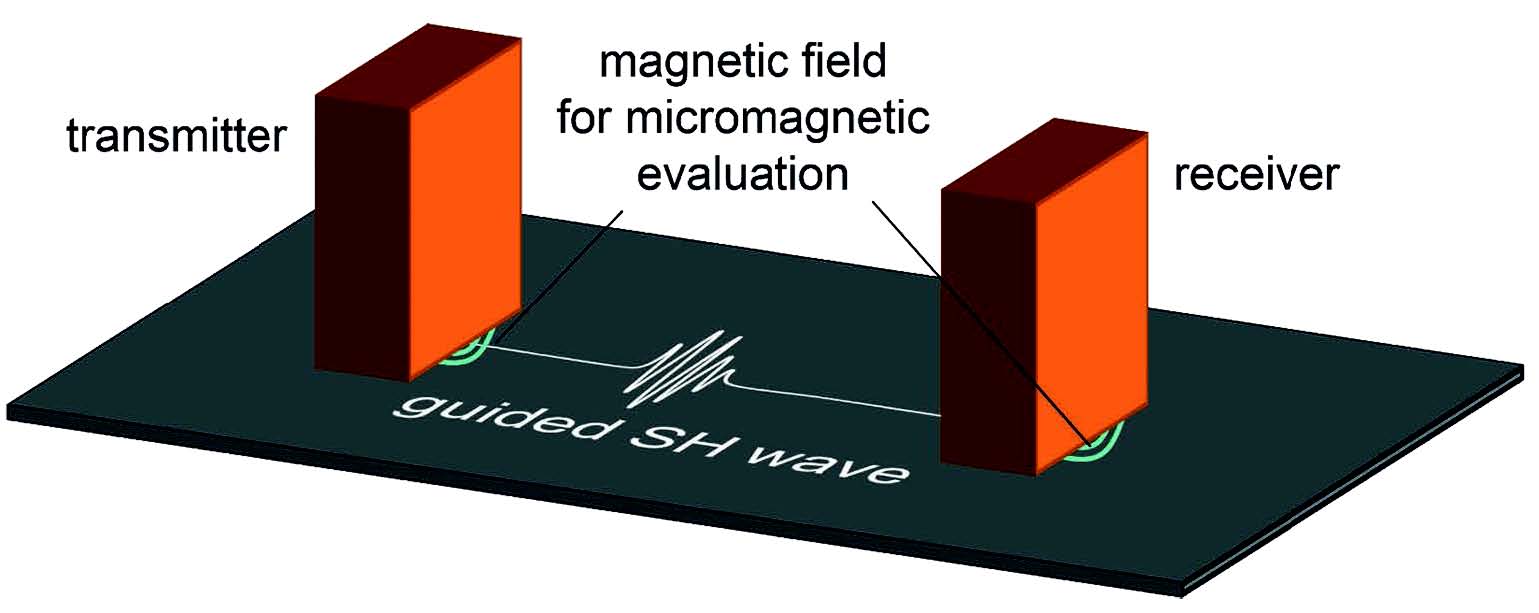

Basic Priciple of micromagnetics / ultrasonics combination

Basic Priciple of micromagnetics / ultrasonics combination

A method for the contactless, process-integrated and fast (real-time) determination of the most essential quality parameters of regular steel and AHSS: Yield strength(Rp0.2), Tensile strength(Rm), texture, grain size and secondary phase content in addition to flaw detection.

A smart and rugged “hybrid probe” which uses synergies between its internal components in order to operate as both electromagnetic acoustic transducer (EMAT) and micromagnetic sensor (ie. not just combining EMATs and micromagnetic probes, which leads to high costs).

A cost-efficient solution for connecting and synchronizing multiple “hybrid probes” to the measuring system in order to measure the distribution of the properties across the width of the strip (rather than just at one position as in the state of the art).

A method of maintaining an air gap and a procedure / an algorithm of lift-off in fluence compensation in order not to touch the strip and still obtain reliable results.

Measuring speed increased by approximately one order of magnitude as compared to the state of the art, allowing for sufficient surface coverage at high strip speeds and with multiple probes.

A combination of technical improvements and software tools which ensure the fast return to normal operation in case of a probe or device replacement which currently required a time-consuming recalibration.

|

|

Destructive tests on random samples can be replaced by nondestructive in-line testing with high surface coverage of yield and tensile strength, texture, grain size and secondary phase content, making process and products safer, greener and less expensive.

Measuring accuracy and speed, robustness of the approach and surface coverage are higher than those of existing systems – at affordable costs.

Strong efforts towards standardization of the method will be started and strategically pursued for the benefit of the full value chain of the steel production.

Well-documented in its characteristics and suited for all kinds of strip steel including AHSS.

Guidelines will be created and a transnational workgroup will be initated to take care of applications and further developments for the synergy of EMAT and micromagnetics in other fields of application.

MAGNUS interlinks Fraunhofer IZFP’s scientific, methodical and technological expertise in the field of electromagnetic NDT with industry orientation systems in the industrial environment. The combination of scientific-technical excellence and the tailored application with respect to industrial needs ensures the creation of tailor-made innovation.

For more details, please contact LAB GAGES directly.

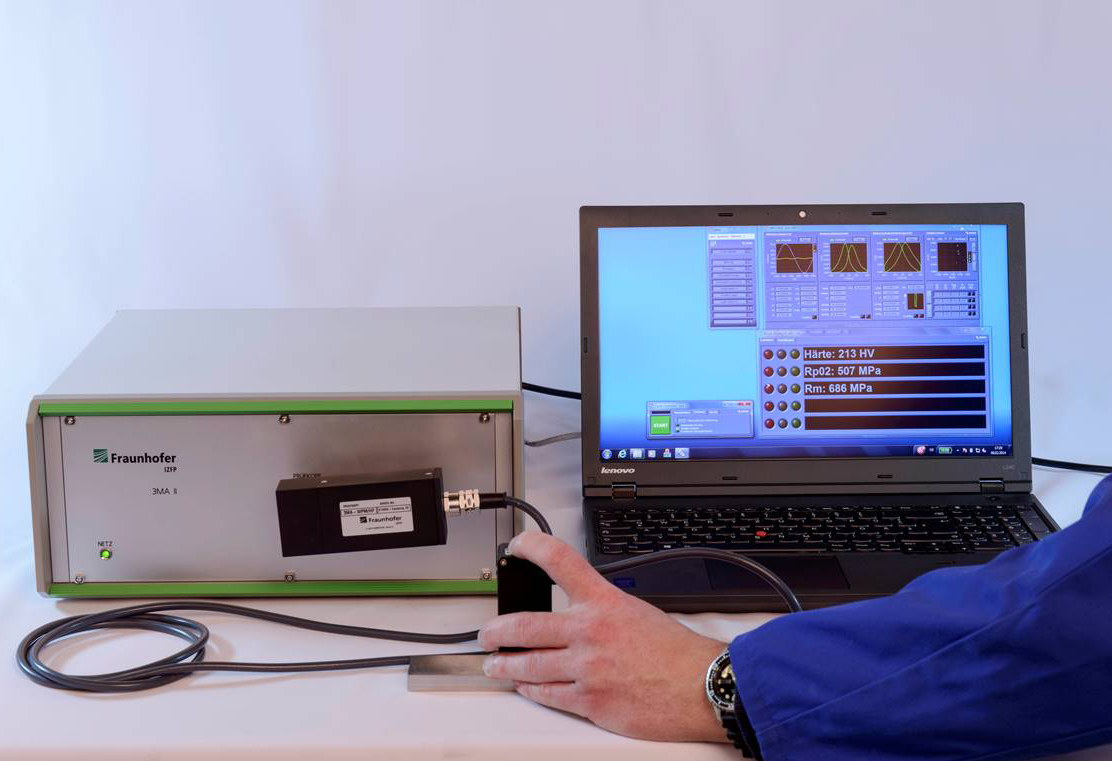

3MA THD Multi-Function Measuring Instrument

3MA THD Multi-Function Measuring Instrument 3MA-X8 System for Fast Materials Characterization

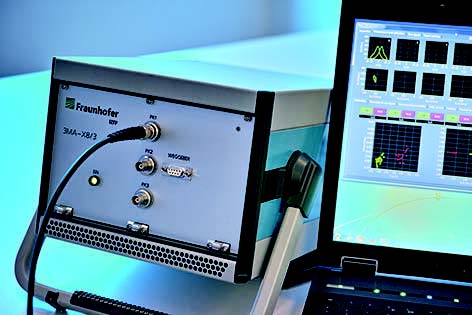

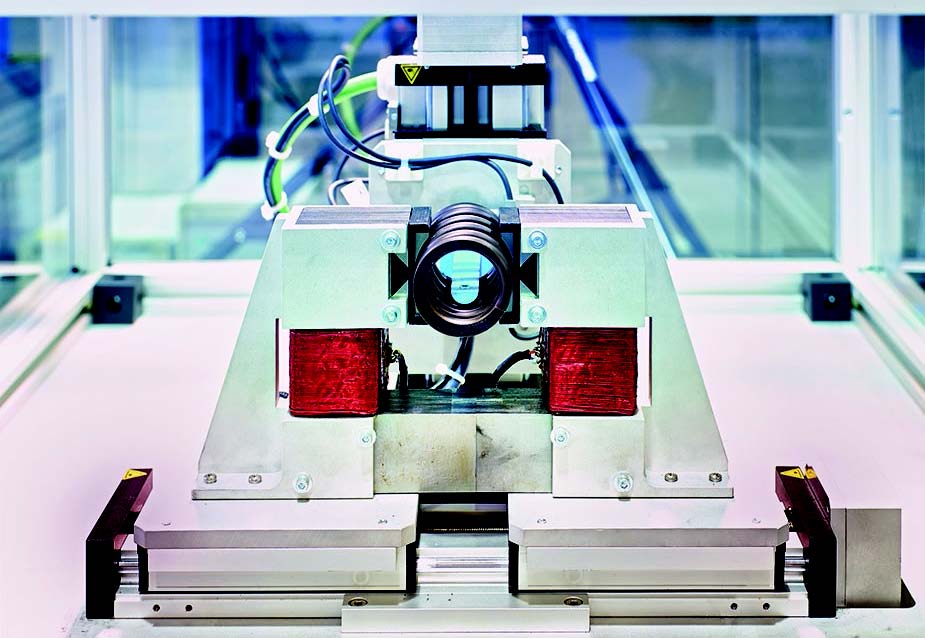

3MA-X8 System for Fast Materials Characterization Hardness & Residual Stress Depth Profiles NDE Scanner

Hardness & Residual Stress Depth Profiles NDE Scanner 3MA Inspection of Press Hardening Parts

3MA Inspection of Press Hardening Parts Barkhausen Noise and Eddy Current Microscope BEMI

Barkhausen Noise and Eddy Current Microscope BEMI Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel

Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel 3MA-SOM steel online monitoring system

3MA-SOM steel online monitoring system 3D SmartInspect-Intelligence in Inspection and Quality Control

3D SmartInspect-Intelligence in Inspection and Quality Control

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號(hào)

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES